Excel for Production Planning

Throughout our experience consulting the implementation of ERP – Enterprise Resource Planning – and MRP – Material Resource Planning – we have seen some outstanding and dangerous examples of how Excel can be used for manufacturing production planning.

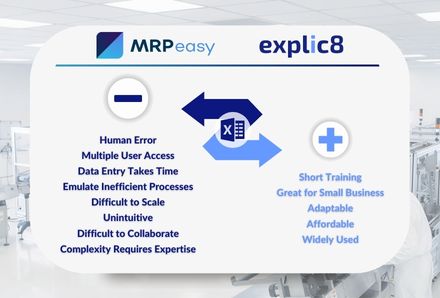

Whilst we believe that Excel will always have a place in the world of business there are aspects that production planners need to be aware of.

Ultimately, Excel is cheap and easy to use for most employees, but as a manufacturer begins to increase their production complexity Excel becomes less reliable and accurate when managing larger-scale operations.

Limitations

Scalability of Excel to meet the ever-changing and growing needs of a successful manufacturer. As a manufacturer seeks to expand their operations so too does the Excel planning document, which can quickly become overburdened and unfit for purpose.

When production becomes more complex, there becomes a requirement for an in-house Excel expert, which can leave a company vulnerable to their absence or resignation. When replacing an in-house expert to control the Excel, they will need to first begin to understand the inner workings of the Excel, which may mean features are removed or underutilised due to misunderstanding.

As an Excel sheet becomes more complex, there is an increased likelihood that the software will begin to experience frequent crashes and data loss. Causing frustration throughout the workforce and increasing the time spent duplicating or correcting completed tasks.

Accessibility issues can occur when using Excel, as more and more employees begin to enter information manually, often they can overwrite or incorrectly edit data causing issues further down the line.

Often production planning can occur inside Excel where it can be difficult to create an accurate master production schedule that will take into account production capacity, bills of materials and routings. This information is then difficult to tie into procurement, purchase orders or financial software.

Opportunities

Granted there are advantages to using Excel as there is little cost of the software package, being bundled into an Office 365 membership that most businesses already require to operate.

The basic functions of Excel are accessible to most employees, being the world’s most popular spreadsheet software. Due to this fact, training requirements are quick and cheap for organisations.

It is possible to create a planning document that feels truly unique to the current organisation’s structure, but one aspect to note, this could also mean that inefficient processes are being transcribed into a digital form.

Excel production planning is most useful for micro businesses that are looking to get their operations off the ground quickly and efficiently. In these types of organisations, there are limited employees with the overall control usually held by the company owners.

How does a growing manufacturer transition away from Excel as their predominant production planning tool?

Enterprise Resource Planning Software as an Excel Replacement

There are solutions such as MRPeasy that have been developed from the ground up to deliver intuitive cloud-based manufacturing planning software to get your business moving in the right direction.

MRPeasy encompasses all of the elements a growing manufacturer needs such as customer relations management, shop floor production reporting, production planning, stock control, procurement and accounting. To read more about the features of MRPeasy please read our other article What is MRPeasy?

If you would like to read more about the opportunities and limitations of Excel and how an MRP system could be the correct solution for your business, please see the below article:

SIGN UP FOR A FREE TRIAL CLICK Here

TO READ THE ARTICLE CLICK Here

- MRPeasy’s Customer Support – What You Need to Know - 19 December 2023

- The Importance of MRPeasy in Managing Your Inventory and Supply Chain for Small to Medium-Sized Manufacturers - 16 November 2023

- Maximising Efficiency with MRPeasy: Tips and Tricks - 15 October 2023